Prototype testing at innolectric

From development to prototype testing

At innolectric, we collaborate to ensure that charging electric vehicles will be reliable, efficient, and convenient in the future. We closely follow developments in electric mobility. What requirements will vehicles have? Which norms and standards are becoming established? What international trends are shaping the market? We use this information to continuously develop our products.

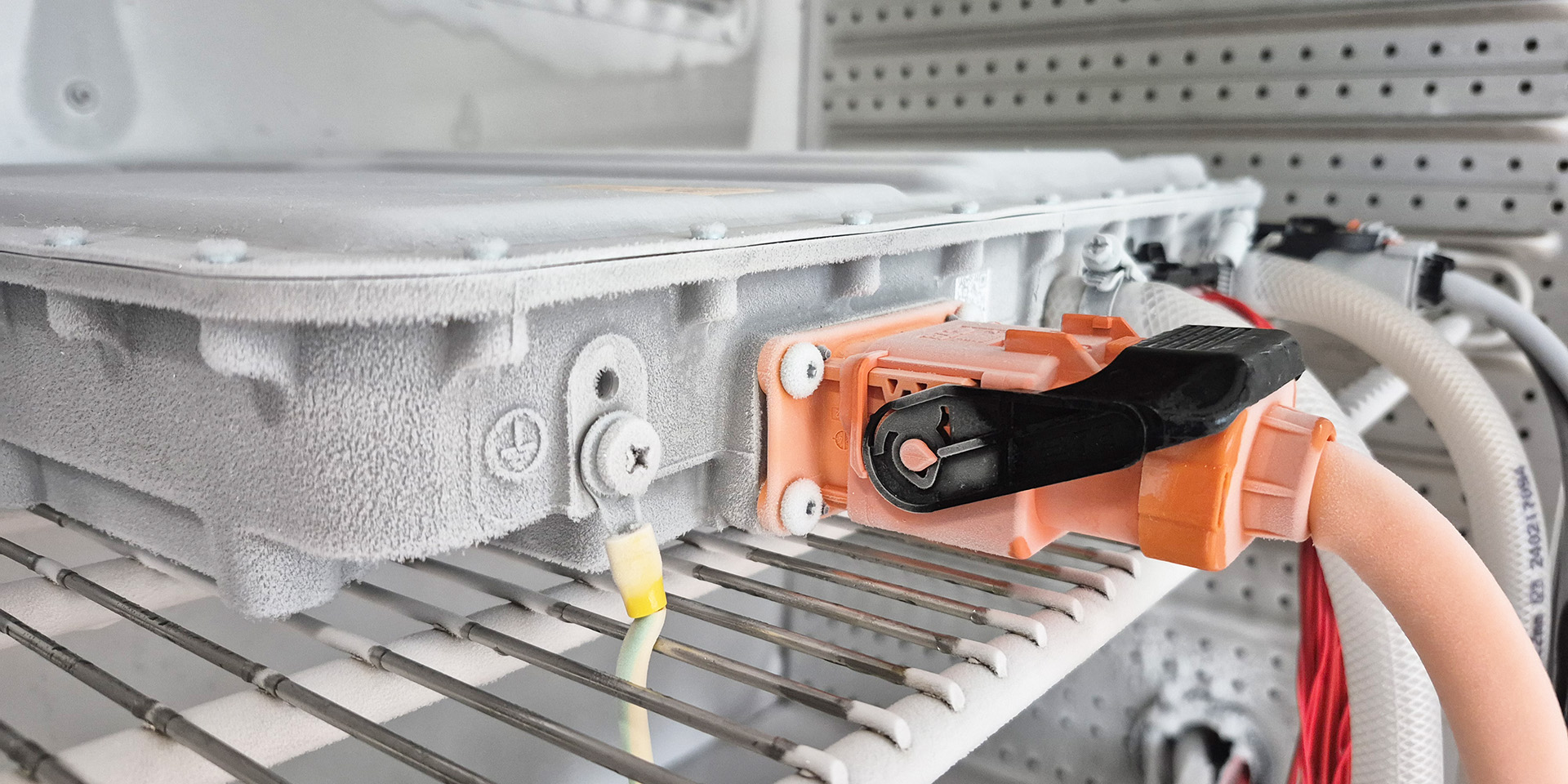

Prototypes in the lab: The first test

It is an exciting time when the first prototypes of a new device arrive at our laboratory. We test: Does the component design work as planned? How does the device react in real environmental conditions?

Our test engineers carry out checks according to the specifications of the ISO 16750-4 standard, which describes the climatic stresses on vehicle components. These include, among other things:

- Temperature tests: Checking functionality at extreme temperatures.

- Temperature shock tests: Simulating rapid temperature changes.

- Humidity and heat tests: Evaluating resistance to high humidity and temperature.

- Storage tests: Long-term storage under extreme climatic conditions.

We implement these test scenarios directly on our prototypes. Our CEC 22 kW onboard charger prototype has successfully passed all internal tests. The innolectric on-board charger withstood extreme heat of up to +75°C and cold temperatures of down to -40°C.

Close cooperation enables rapid optimization

When action is required, our CAD, hardware, and testing teams work together immediately to find solutions. Thanks to our comprehensive in-house development capabilities, we can significantly shorten development cycles and implement complex adjustments in a short period of time.

Our test routines also enable us to efficiently test and finalise customer-specific samples, ensuring the highest quality and safety.