From the idea to series production – insight into the innolectric laboratories

innolectric stands for products with quality “Made in Germany”. From the initial idea to product development ready for series production, components for electric mobility are created in Bochum. Hardware and software work closely together and extensive tests in the company’s own laboratories enable a quick evaluation of the project progress.

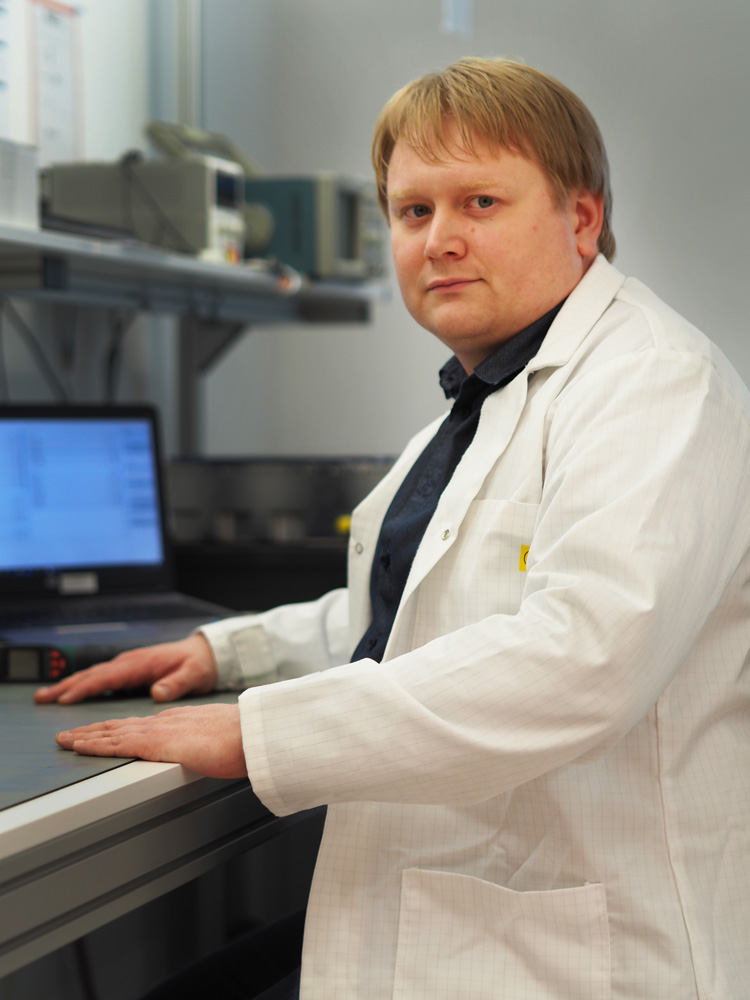

Alex is Team Manager in the area of Testing and Qualification and Laboratory Manager at innolectric and ensures that products such as the innolectric On-Board Charger are continuously tested in the company’s own laboratories and prepared for the start of series production. In an interview he talks about his daily work at innolectric.

Alex, you are responsible for the laboratories at innolectric. What exactly are you in charge of?

As laboratory manager I am responsible for the administration of our laboratories. Organizational management includes the coordination of laboratory resources, such as the distribution of workstations and the technical equipment required for tests. I also ensure that the necessary equipment is available at all times and can be used safely. I also take care of the training of my colleagues. I have to make sure that the laboratory environment is a safe place to work and that all laboratory employees know at all times how to work safely in the laboratory. After all, we work in the laboratory in life-threatening voltage ranges, which are invisible but a great danger. At the same time, I myself, as a test engineer, carry out my own test series with the innolectric products.

What tasks are performed in the laboratories?

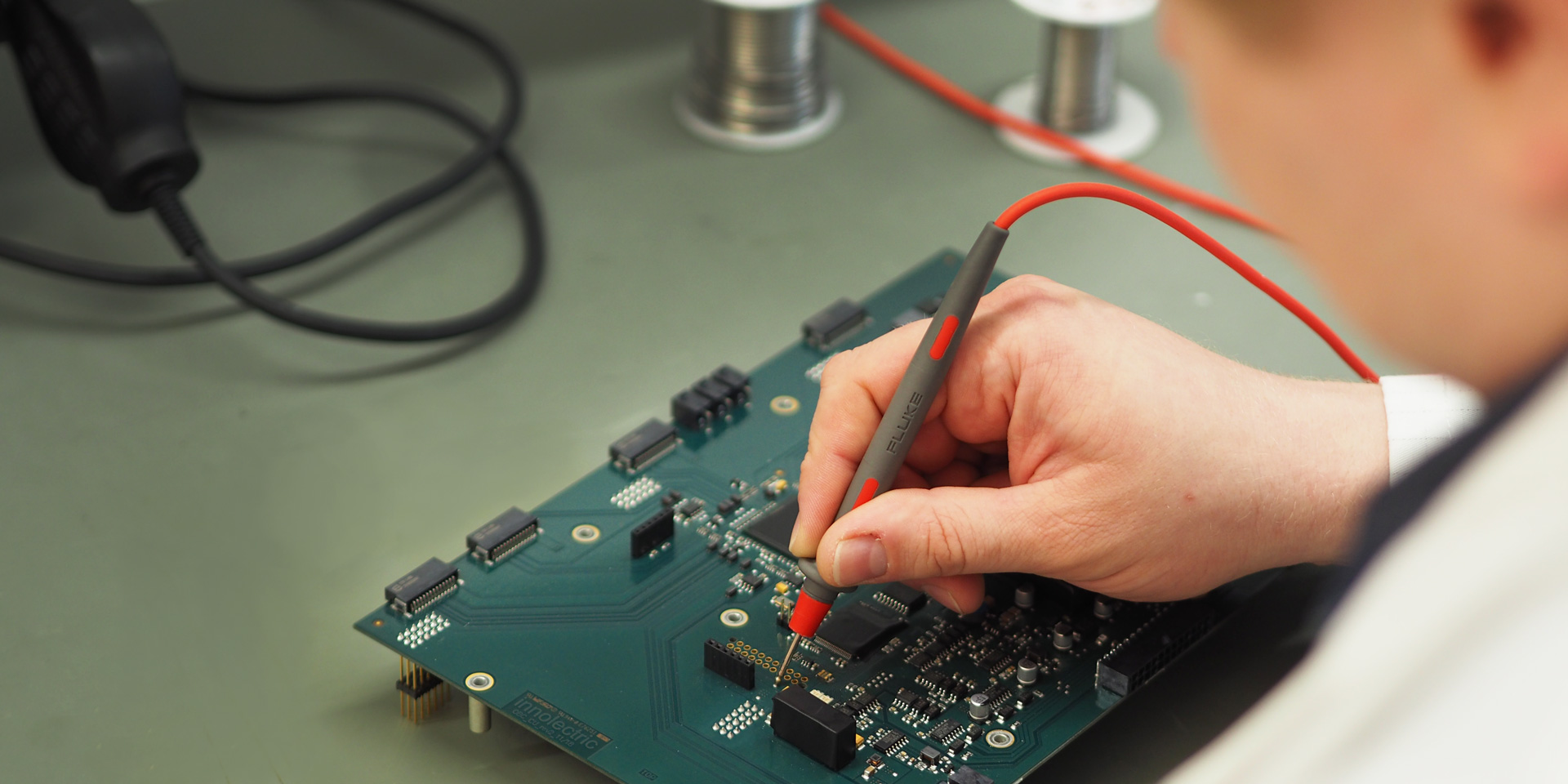

In our laboratories, hardware, software developers and test engineers meet and work together on many levels. In the first step, for example, the colleagues from hardware development design the layout of a product and then test and measure finished assemblies or prototypes directly in the laboratory.

In the next step, the software for the product is tested. All this is accompanied by test engineers who have to ensure that the products are developed in accordance with all relevant standards. A certain amount of creativity is also important – for example, to create realistic test cases and test sequences.

In short, working in the laboratory is therefore a constant interaction between colleagues from different teams, which ensures that the development of our products is driven forward.

What tests do you carry out here on site exactly?

We develop and set up test benches with which we simulate the environment in which our product will later work – for example, an electric commercial vehicle. This enables us to test the functionality under realistic operating conditions in addition to the usual verification and validation tests. Our hardware and software developers benefit greatly from the fact that the testing process takes place directly on our premises. In this way it is always possible to receive feedback from the test engineers during the development process. This shortens the coordination paths massively. I also believe that many of our colleagues are pleased to have the chance to experience the integration on the prototype in our laboratory after a long development phase and to see the first results directly.

What does the work of the colleagues during Corona look like? Is everything you describe possible at the moment?

It is definitely a little different than before. However, thanks to the hygiene concept established by innolectric, working in the laboratories is still possible, but with some restrictions. We pay attention to the minimum distance in the laboratories and work with mouth and nose protection. In these special times, laboratory organization is more in demand than ever. You have to plan very carefully who and when is working in the laboratory so that the flow of development can continue in the best possible way and is not restricted.

Alex, you originally started at innolectric as a working student. What makes managing the laboratory particularly exciting for you?

I started at innolectric a little more than two years ago as a working student in the Battery Systems division. My project was the optimization of an “end-of-line” test stand. Then I started working as a test engineer at innolectric. I was strongly involved in the setup of the laboratories from the beginning. This led to the fact that I took on more and more responsibility over time and finally got the role of a laboratory manager.

Today, as team manager in the Testing and Qualification department and laboratory manager, I accompany the development process in all its individual components, such as electrical engineering, mechanics and also software. As a qualified electrical engineer, this gave me the chance to gain a lot of experience in other areas as well. This diversity makes my daily work here especially interesting and exciting.

Thanks for your time!